Busbar Systems – Efficient Power Distribution by Enersam

Introduction to Busbar Systems

In modern electrical infrastructure, busbar systems by EAE play a crucial role in ensuring efficient, safe, and reliable power distribution. Whether for industrial, commercial, or residential applications, busbars provide a compact and flexible alternative to traditional cable-based power distribution. At Enersam, we specialize in high-performance busbar systems designed to meet the growing demands of energy-efficient and scalable electrical solutions.

What is a Busbar System?

A busbar system is a modular electrical distribution system that consists of insulated copper or aluminum bars used to conduct electricity within a building, factory, or power grid. Busbars replace traditional cables, offering a streamlined and space-saving solution for electrical distribution.

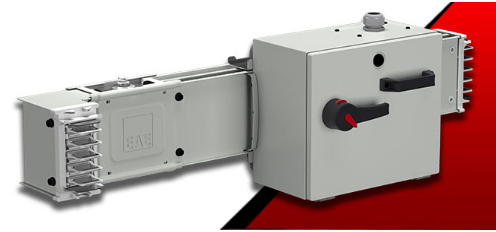

Key Components of a Busbar System

Conductors – Typically made of copper or aluminum, they efficiently transfer electrical power.

Insulation – High-quality insulation materials prevent short circuits and ensure safety.

Housing/Enclosure – Provides mechanical support and protection from environmental factors.

Joints & Connections – Securely connect different sections of the system for optimal conductivity.

Advantages of Busbar Systems Over Traditional Cabling

1. Higher Efficiency & Reliability

Busbars have lower electrical resistance compared to traditional cables, reducing power loss and increasing efficiency. Their sturdy construction ensures durability and minimizes voltage drops.

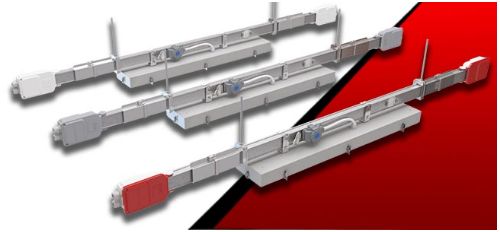

2. Space-Saving & Compact Design

Busbars require significantly less space compared to cables, making them an ideal choice for buildings and industrial settings with limited space.

3. Enhanced Safety

With superior insulation and enclosed designs, busbar systems reduce the risk of electrical faults, short circuits, and fire hazards.

4. Scalability & Flexibility

Unlike fixed cabling systems, busbars allow for easy expansion, modification, and reconfiguration, making them ideal for dynamic and growing businesses.

5. Cost-Effective Installation & Maintenance

Busbar systems require fewer materials and a simplified installation process, leading to lower labor and maintenance costs in the long run.

Applications of Busbar Systems

1. Industrial & Manufacturing Plants

Factories and manufacturing units require high power loads for machinery and equipment. Busbar systems efficiently distribute power across production lines, ensuring seamless operations.

2. Commercial Buildings & Offices

High-rise buildings, shopping malls, and office complexes use busbars to distribute power to various floors and sections, enhancing energy efficiency and safety.

3. Data Centers & IT Infrastructure

Busbars provide reliable power distribution for data centers, ensuring uninterrupted operations for servers and networking equipment.

4. Renewable Energy Systems

Solar farms and wind energy plants benefit from busbar technology to manage high-voltage power transmission efficiently.

5. Railways & Transportation Networks

Busbar systems are widely used in railway stations, airports, and metro networks to power infrastructure and operational facilities.

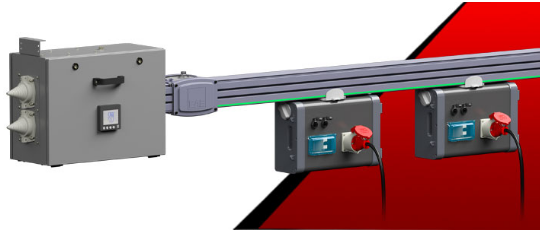

Types of Busbar Systems Offered by Enersam

At Enersam, we provide a diverse range of busbar systems tailored to meet different power distribution needs:

1. Low Voltage Busbar Systems

Designed for commercial and residential applications, low-voltage busbars (up to 1000V) provide reliable power distribution for lighting, HVAC, and other electrical systems.

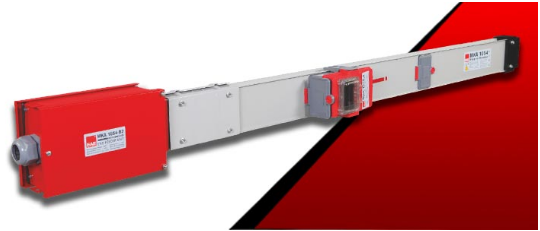

2. Medium Voltage Busbar Systems

These are used in industrial and commercial facilities where voltage ranges from 1000V to 35kV, ensuring efficient power management for machinery and infrastructure.

3. High Voltage Busbar Systems

High-voltage busbars (above 35kV) are utilized in power transmission and distribution networks, ensuring minimal energy loss over long distances.

4. Cast Resin Insulated Busbars

For environments requiring superior insulation, cast resin busbars provide excellent electrical and mechanical protection, preventing overheating and short circuits.

5. Aluminum & Copper Busbars

Depending on application needs, we offer copper busbars for higher conductivity and aluminum busbars for cost-effective and lightweight solutions.

Why Choose Enersam Busbar Systems?

✅ Superior Quality & Performance

At Enersam, we adhere to the highest industry standards, ensuring that our busbar systems deliver optimal performance, durability, and efficiency.

✅ Customizable Solutions

We offer customized busbar configurations to match your specific power distribution requirements, ensuring seamless integration into your infrastructure.

✅ Expert Engineering Support

Our team of experienced engineers provides comprehensive support, from system design to installation and maintenance.

✅ Compliance with International Standards

Enersam’s busbar systems meet all necessary safety and performance regulations, including IEC, ANSI, and UL certifications.

✅ Competitive Pricing & Cost Savings

We provide cost-effective solutions without compromising on quality, helping businesses optimize their power distribution systems within budget.

Installation & Maintenance of Busbar Systems

Step-by-Step Busbar Installation Process

Site Analysis & System Design – Assessing power distribution needs and designing an optimal busbar configuration.

Component Selection & Customization – Choosing the right busbar type, material, and insulation based on application requirements.

Installation & Connection – Ensuring precise alignment, secure fastening, and proper insulation of the system.

Testing & Safety Checks – Conducting voltage, load, and insulation resistance tests to ensure reliability.

Commissioning & Ongoing Maintenance – Regular inspections, cleaning, and preventive maintenance to maximize lifespan.

Maintenance Tips for Busbar Systems

Regular visual inspections for signs of wear, corrosion, or overheating.

Tightening of joints and connections to prevent power loss.

Periodic thermal scanning to detect potential faults.

Cleaning of insulation and enclosures to maintain efficiency.

Frequently Asked Questions (FAQs)

1. What is the lifespan of a busbar system?

With proper maintenance, busbar systems can last 30+ years, making them a long-term investment for electrical infrastructure.

2. Are busbars safer than traditional wiring?

Yes, busbars reduce fire risks due to their enclosed structure, superior insulation, and better heat dissipation.

3. Can busbars be upgraded or expanded?

Yes, one of the biggest advantages of busbars is their modular design, allowing easy upgrades and modifications.

4. What is the cost of installing a busbar system?

The cost depends on factors such as voltage rating, material (copper or aluminum), insulation type, and installation complexity. Contact Enersam for a tailored quote.

5. How do I choose the right busbar system for my needs?

Our expert team at Enersam will assess your power requirements and recommend the best busbar solution tailored to your application.

Get in Touch with Enersam Today!

If you’re looking for a high-quality busbar system that ensures efficiency, reliability, and cost-effectiveness, Enersam has the perfect solution for you. Whether it’s for industrial, commercial, or residential use, our expert-engineered busbars guarantee seamless power distribution.

📞 Contact us today to learn more about our products and get a customized quote!